Hope is a company that we believe needs no introduction. Surely even the most novice biker will have noticed the famous English brand and their components that cannot go unnoticed. What mainly distinguishes Hope from the other brands is above all, the rigorous and obsessive CNC machining. A clearly distinguishable hallmark, even to the untrained eye. The classic lines are deliberately left in relief to delight the palate of those who appreciate their aesthetic.

HB.130 at a glance

- Category: Trail bike

- Frame material: Carbon, billet aluminum rear end

- Wheel format: 29″

- Available sizes: Medium, Large, X Large

- Suspension system: 4 link bars with Horst joint

- Adjustable geometry: yes (+ – 0.5 °) by flip chip

- Front/rear travel: 140/130 mm

- Boost: No, they use their own 130x17mm system

- Metric shock: yes

- Tubeless ready wheels and tires: yes

- Drivetrain: 1 × 12 with 30T chainring / 175 mm cranks

- Front derailleur mount: no

- ISCG attack: no

- Chain guide attachment: yes

- Bottle cage attachment: yes

- Frame availability only: yes

- Size in test: L

- Tester height: 181cm. Saddle height (saddle-bottom bracket): 78cm.

- Weight: 13 kg claimed (it was not possible to verify it)

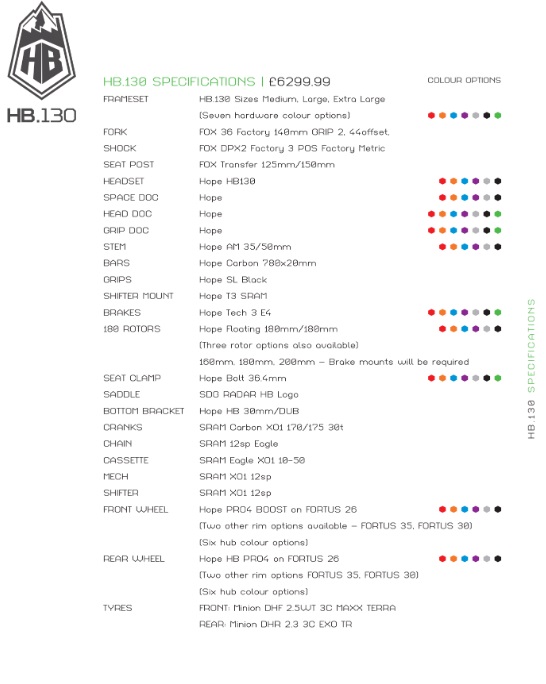

- Price: standard spec bike € 7500

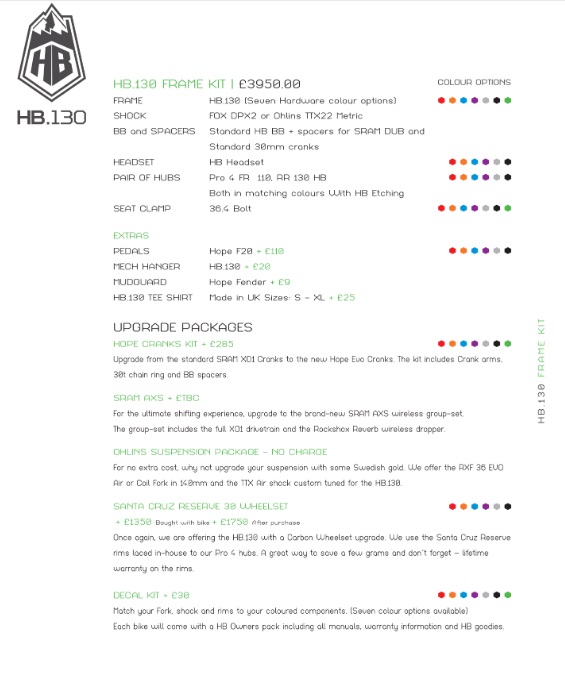

- Frame kit: € 4700 including FOX DPX2, or Ohlins TTX22, hubs, headset, seat clamp and bottom bracket.

- Upgrades (added to the base price):

- Hope crank kit € 360

- Sram AXS group and Reverb € 1440

- Ohlins fork and shock upgrade: no charge

- SC Reserve carbon wheelset € 1695

- Decal kit for fork, shock and rims € 36

Doddy (Hope mechanic and good rider) helps me out with the setup.

Static analysis

It’s difficult to pigeon hole the HB.130 in a very specific category. I’d call it an aggressive trail bike.

Large cable passages make things a bit easier, but have no internal guiding.

No detail left to chance.

At first glance, the HB.130 appears harmonious and elegant with a compact main triangle that can still accommodate a bottle up to 750cc. Slender lines that go against the trend compared to other brands take advantage of the features offered by carbon fibers to create oversized box sections, especially in the bottom bracket and steering area.

From above the HB.130 looks very slim.

The aluminum rear triangle has chainstays machined from a solid mass, and seatstays that have a central section in extruded aluminum with a triangular section. This extrusion is glued on one side with the dropouts and on the other with a Y-shaped element that transmits the forces to a link (also rigorously tooled from a solid block) to which the metric shock is connected.

By leaning on the reliability of the bonding technique, the Hope engineers say that in destructive tests the aluminum fails first and then the glue. The rear suspension has a 4 bar linkage with a Horst pivot, the link where the shock is located generates a lever ratio of 2.6. The designer told us that he designed the very progressive suspension scheme so that it could also adapt to coil shocks. The HB130 is available with Fox or Ohlins suspension, both with custom tuning to best suit the suspension characteristics.

The upper part of the rear triangle that is glued to the extruded intermediate sections of the seat stays.

The HB.130 was designed around 29 “wheels without the option of using other formats. The only variable is the adoption of flip chips to vary the head angle by approximately 0.5°. The elliptical plates are positioned at the lower linkage of the shock: varying the position from high to low is relatively simple but it is not meant to be changed “on the fly” on trail. In the low position, the bottom bracket is lowered by 6mm.

The HB.130 is available in various versions which can also be customized with the anodized colors of the Hope components, including stickers for the rims that match the colors of the other components. The frame instead is only supplied in visible carbon, treated only with a layer of protective lacquer.

Detail of the dropouts made from solid, oversized 17mm axles with internal and external hex wrenches. Horst link. All joints rotate on ball bearings.

Speaking of anodizing it is important to highlight the difficulties of obtaining the same colors in different production times and the instability of the chemical oxidation process, Hope has equipped themselves to manage this delicate production phase directly in house. With great range in how colors can turn out depending on material batches, this is an arduous process, to say the least.

Hope offers 7 color combinations

As for the non-boost rear hub, the solution adopted at the rear is rather unique. Instead of using the classic 148mm hub (boost), Hope decided to create their own solution that had already been introduced with the HB.160. The oversized 17mm axle is inserted into the dropouts and passes through the hub where the wheel is mounted on the frame. This solution ensures greater rigidity at the rear, according to Hope.

Another peculiarity is that the spokes of the rear wheel are absolutely symmetrical, guaranteeing an ideal, even tensioning. Hope has gained space on the non-drive side of the hub by bringing the rotor mount closer to the flange where the spoke heads are located. This solution reduces the total width of the rear end of rear triangle to provide more space for your heels.

Rubber protection of the lower part of the frame

Regarding the brake mount Hope returned on its senses compared to the radical solution used on the HB.160 which, albeit rational, limited the choice of brakes to only Hope products. Now the HB.130 has opted for a more common post mount which therefore fits all major brake brands.

Internal routing: there are two access ports in the steering area that are large enough to allow the cables to enter through a section of foam sheath to avoid flapping noises in the frame. This is Hope’s preferred solution to guided internal routing. In the test I didn’t notice any noise from contact inside the frame.

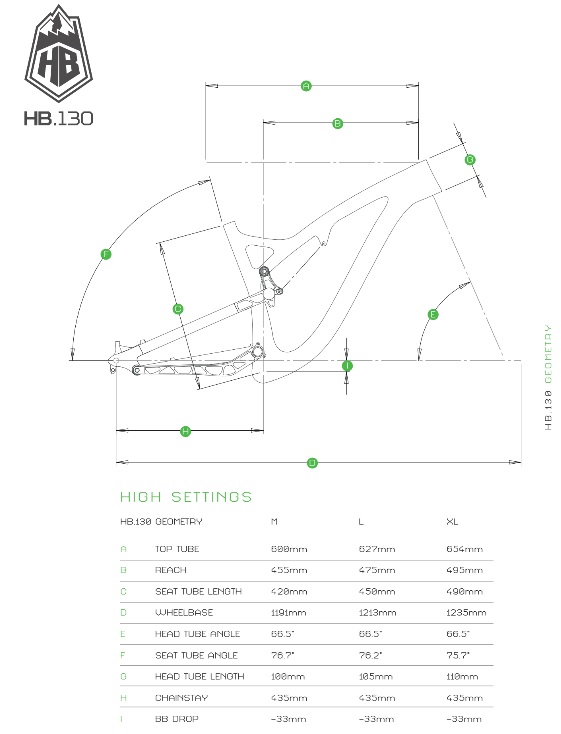

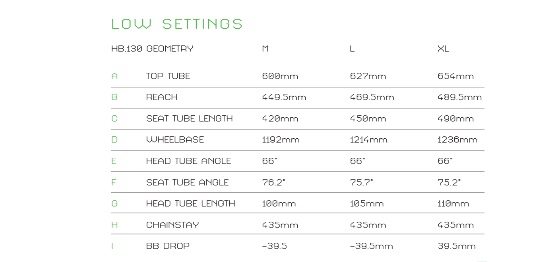

Geometry

Hope has aligned itself with many of the latest trends. Long reach combined with a short stem and above all a steep 76° seat angle. Lastly, a 65.5° steering angle combined with a classic 51mm offset fork.

On the trail

Doddy, the Hope team mechanic, prepared an HB.130 in a size L mounted with an Ohlins fork and shock. After having thoughtfully reversed the position of the Hope Tech 3 E4 brakes, given that the English use the front brake with the right lever, I set the sag at about 25% rear and slightly more for the fork.

As always I give much credit to the initial sensations that a new bike transmits to me. I must say that after the first few meters the HB.130 gave me a feeling of solidity that was out of the ordinary. Of course, this feeling can also partially come from the rigidity of wheels and fork, but I certainly perceived it. The position in the saddle seemed immediately familiar, similar to the Ibis Ripmo I usually ride. A 780mm wide handlebar, 50mm stem and 470mm reach combined with a fairly steep saddle angle provided me with a position where it was easy to put weight on the front wheel.

Smooth climbs

Both on asphalt and then on the dirt road the HB.130 climbs well and the suspension does not oscillate. I moved the shock lever to the “trail” position but the difference is really almost imperceptible. On the climbs on asphalt I appreciated the possibility of closing the fork’s compression, which has a much more noticeable effect than on the shock. The low weight, but not featherweight, of the bike and the relative smoothness of the Maxxis DHR 2.3 make the ascents on firm surfaces pleasant and smooth.

Technical climbs

In the two days of testing we never made use of shuttles or chairlifts, accumulating about 1200m vertical meters a day, adding up the various ascents. It has often happened that we deal with technical sections with steep punches full of obstacles or low traction surfaces. In this area I must say that I had an excellent impression both for the behavior of the rear suspension that hardly sank in the travel and for the geometry that allowed me to remain seated centrally without having to exasperate myself trying to load the front. The front wheel always remains firmly planted on the ground, also guaranteeing excellent steering. It is also fun to try the more direct lines, perhaps hitting a rock instead of going around it. The stable front and the abundant traction allows you to overcome difficult sections easily, provided that there are still watts in the legs to be transferred to the pedals. I really enjoyed it even in the most extreme climbs.

Descents

In Scotland we have tested various types of trails and terrain. Clearly, here there are no long rocky descents that break your hands typical of the Alpine territory, on the other hand there are fun natural or partially built trails with berms and fun passages through steep rocks. The descents were on average 3-400 vertical meters long but depending on the pitch they could also last a long time. The trails, however, forced people to keep a very active riding style.

The HB.130 has always responded well to my input to the handlebar as long as the front is loaded well. After some descents I became familiar with the front, also thanks to the Maxxis Minion DHF 2.5WT 3C and to the Ohlins fork which turned out to be rigid but not nervous. Entering a turn by putting the weight on the front had the effect that the rear wheel was lightened to the point of skidding and helping to wrap the turns.

The limit can be found or at least perceived with an increase in speed and in the size of the obstacles. I was also able to test the “low” position by reversing the flip-chips: the bottom bracket is lowered by about 6mm and the steering angle opens by half a degree. I must say that I did not find a very measured difference, but I believe that to perceive it, it would have been necessary to repeat the same trail several times changing the settings every time, something that was not possible for due to limitations on time. I would be curious to test the HB.130 on alpine trails, but I think that as an all-rounder, it would be great.

Conclusions

Hope has achieved the goal of creating a fun bike, suitable to all different types of trails, a great allrouder with modern geometry and unique solutions. The HB.130 easily climbs everywhere and in the downhills will keep you grinning. It uses new, effective and elegant solutions, such as the hub / rear axle and the bottom bracket shell. The HB.130 must therefore be understood as a product in its own category.

If you love mechanics and products that are born out of passion and love for technology and you have no problems getting to the end of the month, then you could think about this jewel made in the UK. Certainly not cheap, but it’s an object that is not going to depreciate in short time.

Specs